Few areas of the floor are as prone to bacterial contamination as the gap that runs along the side of the room where the floor meets the wall.

This 90 degree join not only spoils an otherwise seamless and impermeable finish, but it is also extremely difficult to properly clean – making it a ticking time bomb for food production facilities that can’t afford to have germs piling up near the staff, equipment and produce.

The importance of minimising this contamination risk is reflected in the amount of space the issue is given in Australia’s hygiene rules and regulations.

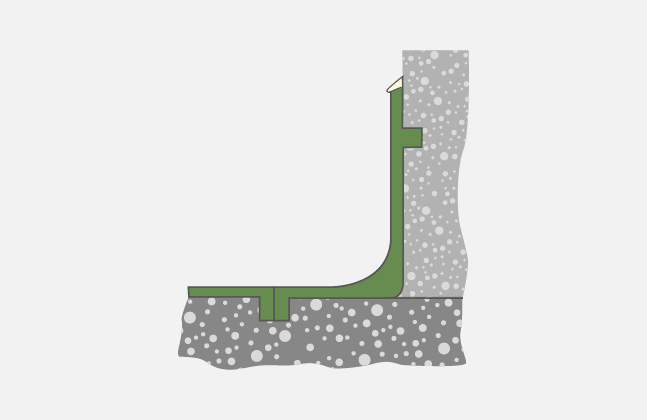

Coving is ideal for smoothing over this gap and creating a seamless, easily cleanable transition between the floor and the wall that leaves dirt, dust and germs without a place to hide.

These are our top five coving tips to help food and beverage facilities ensure a hygienic floor that meets Australia’s food and beverage industry standards.

- We recommend that epoxy coving in kitchens and food processing areas is 100 mm high. In meat and poultry facilities this might need to be raised to 400 mm to account for wall panels that sit on top of concrete plinths. This extra height will stop damage to the walls.

- The number of authorities that stress its installation underlines the importance of coving. This includes HACCP, local councils, Food Standards Australia New Zealand and the Australian Quarantine Inspection Service (which concerns export facilities). If you’re unsure of the specific rules that govern your facility then these are some handy starting points to inform your choice of coving.

- Food Standards Australia New Zealand states that “coving should be provided in new premises in areas where floors are intended to be or likely to be cleaned by flushing with water”.

- Food and beverage facilities may find it useful to install coving behind stoves and food preparation benches to make these areas easier to clean.

- Resin flooring systems can include coving made from the same material as the floor, making it quicker, easier and simpler to specify and install.

If you’ve got any coving questions leave us a comment below or get in touch with the Flowcrete Australia team by clicking here.